For Sindhu and all my other readers,

Last month I went with my houseboat to the shipyard.

I made lots of pictures, but not with the idea to make a blog about this visit to the shipyard.

Later the idea came to make a blog. A vague idea.

Recently I was Whatsapping with Sindhu* [* means see link below] who lives in Tiruvannamalai in India. That gave me the idea to make it for her. So I had my virtual audience and that made clear that it has to be in English.

And I can take the opportunity to make it a bit into a story about my houseboat.

I regret that I didn’t think about this earlier, cause then I would have made more pictures about the actual work that has been done, like the welding.

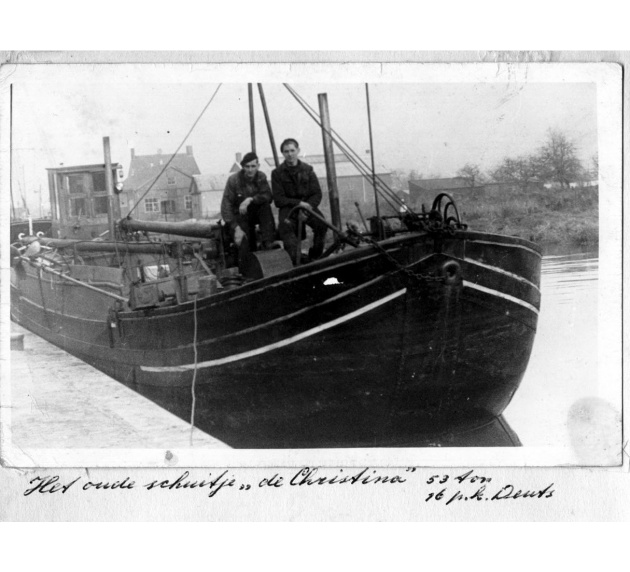

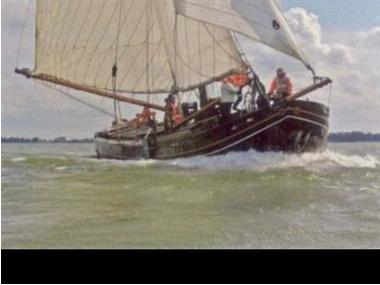

The houseboat was originally an old freight sailboat of the Hagenaar type, which only later had an engine built in.

I took the engine out end 2005, donating it to an engine museum.

I might make a blog about that adventure later.

Let me show you one picture of the engine leaving:

The ship was built in 1907 by shipyard Hendriks in Doodewaard and must have looked somewhat like this one:

Or like this one:

My houseboat is lying alongside the quay and next to it is another ship moored.

This time we, my neighbour and I, decided to go to the warf at the same time, which makes the proces somewhat easier.

(When my ship goes when she is not going, that second boat has to be taken aside and put back again and then a week later the same procedure again. It’s doable but this time we avoided that part).

The process of going to the shipyard has a few distinct steps.

1. The starting position is where the houseboat is moored.

Before departing you have to disconnect all the different connections to the shore.

There is a connection for drinking water,

there is a connection for natural gas,

there is a connection for electricity,

there is a connection for cable tv/internet/telephone,

there is a connection to the sewer system of Amsterdam,

and there is the ropes and a few lashing straps for keeping the ship moored.

2.Then the ordered tugboat arrives.

And the connection to that boat is made and off we go.

Over the radio the captain of the tug asks for the bridges to be opened.

3. The ride to scheepswerf Vooruit** in Zaandam*** takes almost one and a half hour.

4. Being moored at the Shipyard at Sunday afternoon, so the action of getting the ship out of the water can start Monday morning right away. In this case the neighbour’s boat was taken out first.

5. Hauled out of the water and being parked for cleaning the outside bottom with water under high pressure. (240 atmospheres).

6. Relocating the ship for inspection, reparations and a finishing touch of two layers of underwater paint.

7. Alongside and in between all the above, finishing the already in Amsterdam prepared (sanding and anti rust paint here and there) painting of the three colours above the black.

8. launch the boat again with the largest ship lift in the Netherlands.

9. Waiting half a day to make sure the boat is not leaking.

(That happens once in a while and you better find that out at the shipyard, otherwise you have to go back again. This once happened to a neighbouring boat where they asked me for help initially. I made a blog about that event: https://hansvandergugten.nl/?p=4390).

10. Ride home with another tugboat. (Because of a one day delay of my return the habitual one was not available).

11. Reconnecting to the city. Next time again latest in July 2026.

1.

The starting position is close to the Skinny Bridge****, seen here from the porthole at the front of my houseboat.

One connection between the two ships.

The connection to the sewer system taped to the quai.

2.My friend Barbara came along for the outward journey, here waiting for the liftoff.

We had our bikes on board, of course, so we would have a way to transport ourselves.

Behind the tugboat, ready to go.

Leaving behind an empty stretch of quai.

3.

And off we go, looking over the new green sedum roof, the first bridge is already open.

Looking back at the bridge we just passed.

Upfront we see the National Maritime Museum*****, with a replica of the VOC ship ‘Amsterdam’****** moored at its jetty.

The building rising up at the left of the middle of the picture is the NEMO Science Museum*******

At the front is Amsterdam Central Station ******** that we pass at the back.

And as you can see we brought our bikes on board.

One of the IJ ferries.

4. We have arrived. Moored at the shipyard:

Behind the boat you see the blue sided dock that took it out of the water the last two times.

This time it will be done with their newly acquired shiplift, the biggest in the Netherlands. This 12 meter wide monster can lift more than ten times the weight of my ship. Here it is, standing there on a sunny afternoon:

5.

Houseboat Everdina is pulled to the boat lift.

The actual lifting: httpv://youtu.be/V2rejrPul1Y

The move onto land: httpv://youtu.be/5gag5K6U_G4

Parked and ready to be cleaned:

6. Relocating: httpv://youtu.be/mNwJECj5fQc

Ready for inspection:

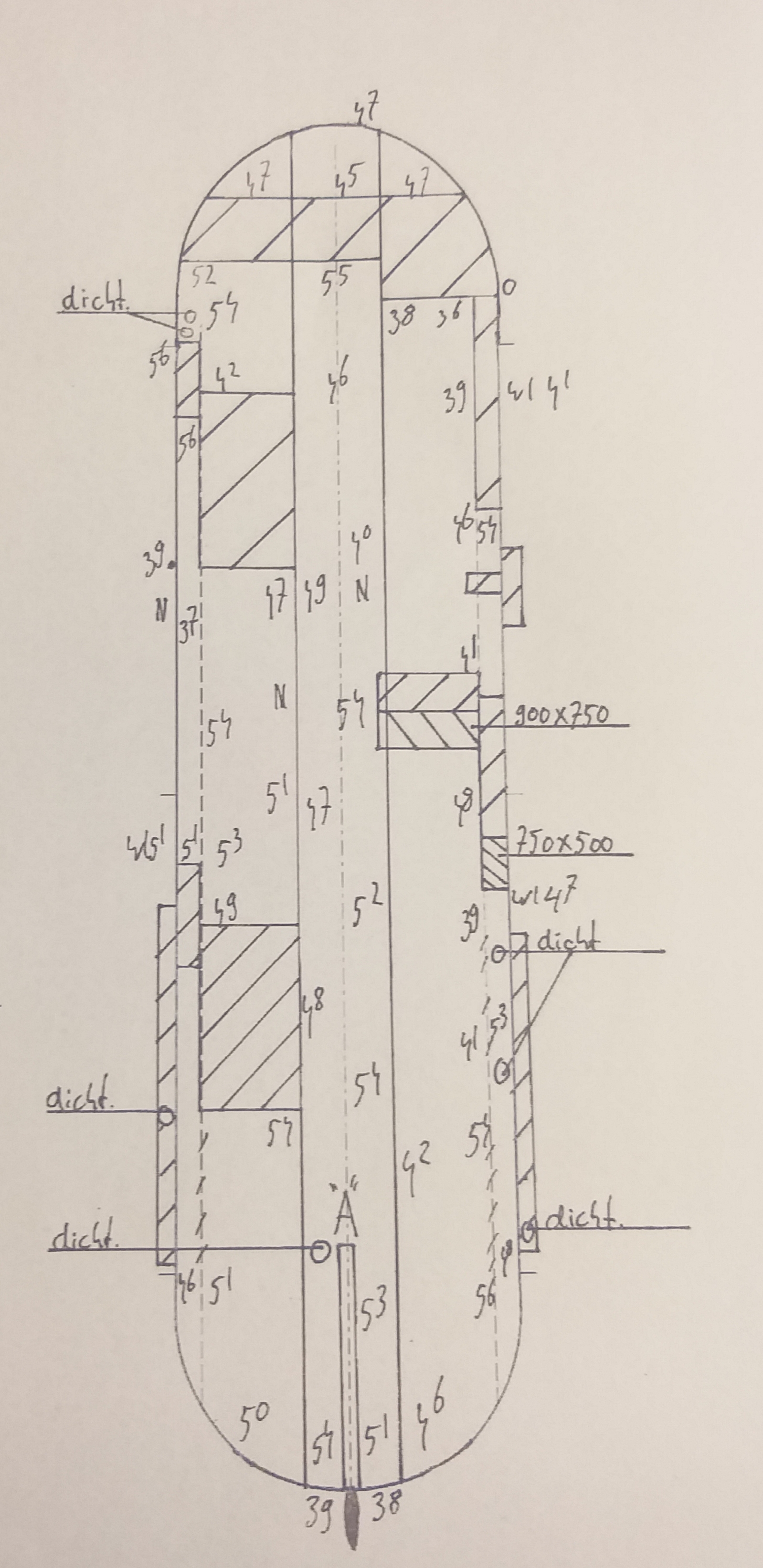

As said, I did only later get the idea of making this blog. So, alas no pictures of the inspector inspecting. I give some pictures of all the marks that where made on the ship. Being instructions for the workers for what to do.

To begin with the drawing from the inspection report:

There were two destroyed by rusting rivets.

Here is one of them, before and after welding:

Before welding metal plates were connected by a technique called riveting. Wiki has a nice page on it. Play the video ‘Riveters work on the Liberty ship SS John W. Brown’ to see how that is done. https://en.wikipedia.org/wiki/Rivet

There were two places where the skin was so thin that pieces of new steel plate had to be welded over it:

With the other plate there was an inconvenience: the place where a new plate had to come was partly covered by the top of one of the eight supports that the ship was standing on.

A minor problem according to the inspector, they will replace it.

And that’s what happened. Their strongest forklift came along and just lifted my ship in the middle a bit, right next to the support, till they could shuffle it a bit to the side. That’s how flexible a ship is.

Done:

Then there were several transits through the ship’s hull that had to be closed. How so? Since six years my houseboat is connected to the Amsterdam sewer system. Untill then all waste fluids were discharged into the river. (Bathrooms, sinks, showers, washing machine). This time was the first inspection since the connection to the sewer system. And all the now unused holes in the hull had to be closed.

A few examples before and after:

After this all it is time to do two layers op spray paint. the first layer is beige gry, the second is black. Here you see them after having done the first layer on the ship of my neighbour and preparing for mine.

First layer of spray painting done:

First layer of spray painting done:

By the way, the black above the water line up till the first colour is a different kind of black paint and is done by hand with a paint roller:

And then ….., all painting done:

7. As mentioned, between those repairs and spraying work, the three color bands that were already prepared and partially completed were finished by Jan:

Blow up:

Intermezzo.

The day before the relaunch there was a kind of special happening in and around the huge shiplift: a big ocean sailer catamaran was being lifted out of the water for inspection. It was being sold and selling a ship normally is done when the ship is in dock or hanging in a shiplift, so that the new owner can see what he is buying. Ofcourse there was another inspector officially doing an inspection of this boat. I have talke to the couple that were the selling owners. They were, like me, from a rather simple background and have been very succesfull in the software industry. At some point they sold their company and started sailing around the world. From this journeys they make blogs and the are in a way a well known attraction in that specific niche of the water world. There is on their youtube channel a lot of footage and especially their footage of being chased forward by a force 10 wind gets enormous amounts of hits. I still haven’t looked at it yet, will do that in a minute.

And will give us here a few pictures of the ‘hanging’ of their ‘cat’ and a link to their Youtube channel and Facebook page.

https://www.youtube.com/c/CatGreatcircle/about

Lagoon 52S Greatcircle for sale. (Too late. Sold).

Lagoon 52S Greatcircle – Windforce 10 to Ibiza

https://www.facebook.com/CatamaranGreatcircle

8. Houseboat Everdina crawling back into the water.

Before we go I’ll show the new anodes. They were not visable yet on the last pictures cause they were taped off during the spraying. There are six in totall around the ship. Here are the two at the rear end.

As said, those things are called anodes. There function is nicely described in a wiki: wiki/Galvanic_anode

https://youtu.be/VDB0qz7sd40

https://youtu.be/VDB0qz7sd40

9. So, back in the water again.

The going back was one day delayed. And the relaunching was one hour delayed because they had to replace another ship before mine could be reached. Because of the delay I had to organize another tugboat and the captain of that one suggested to stay till 18.00 before leaving. In order to have at least half a day for checking if there was no leaking.

The going back was one day delayed. And the relaunching was one hour delayed because they had to replace another ship before mine could be reached. Because of the delay I had to organize another tugboat and the captain of that one suggested to stay till 18.00 before leaving. In order to have at least half a day for checking if there was no leaking.

Also I had a appointment in Amsterdam during this waiting hours with my fysiotherapist. And a friend who could not join for the way back the day before now could come along. So in one go I went for my appointment, picked up my friend Machteld and we had just half an hour for looking around the shipyard and then it was time to go home.

When you see the wheels of the shiplift you see wheels. Only with someone close to it you see that the tyres are just over two meters high:

10. Tugboat has arrived.

Passing Eye Filmmuseum.*********

Back in the Amstel:

Back home:

11. We moored at 19.30. By 21.00 we had all the connections up and working.

12. People often are curious about the cost of such an adventure:

€€€€ – Shipyard visit moneywise – €€€€

Going to the shipyard is ofcourse also financially each and everytime an adventure.

You know that it is coming, but the result of the inspection, resulting in the actual list of repairs needed, is exciting and always a surprise.

And there is nothing you can do about it but wait for the result.

This time it was a eight and a half thousand euro adventure.

Quotation for the shipyard handling € 4.140,31

The total sum of the extra reparations € 3.111,48

Tugboat outward journey € 226,88

Tugboat way back € 363.00

Paint and stuff for the 3 colours € 200,00

Painting the 3 colours € 500,00

_______

Sum total € 8541,67

To end this mostly picturesque report on a more fairylike note,

two pictures of the famous Magere brug.

The first I made on the evening of arriving back:

The seond I made the next day. During the night I happened to glance through a porthole. Normally there is the neighbour’s boat but she only came back from the shipyard the next day.

I took my phone, went up and took this picture:

End of journey.

*Sindhu and I met ten years ago. Since then I’m a supporter. She is

now 18 and studies Chemistry in Tiruvannamalai.

Here the pictures fom 10 years ago: hansvandergugten.nl/?p=1666

** Scheepswerf Vooruit (website)

***Scheepswerf Vooruit location: Zaandam.

****Skinny Bridge

******VOC ship ‘Amsterdam’

*******NEMO Science Museum

********Amsterdam Centraal station

*********Eye Filmmuseum

I love the boat, the stay at home boat, and it’s paint and repAir.

So interesting and well documented! Lovely boat. Thank you for this 🙂